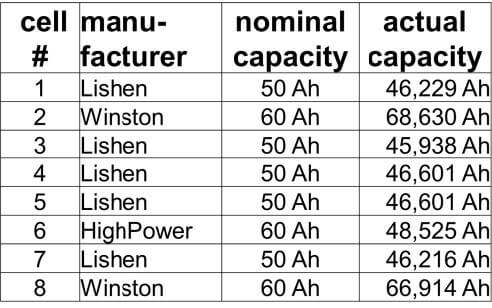

Operating battery cells connected in series – from different manufacturers, of different ages, and at different nominal capacity: ETA-Leveling makes it possible. It is the only charging process available enabling the simple reuse and repurposing of, for example, cells from power storage modules declared defective.

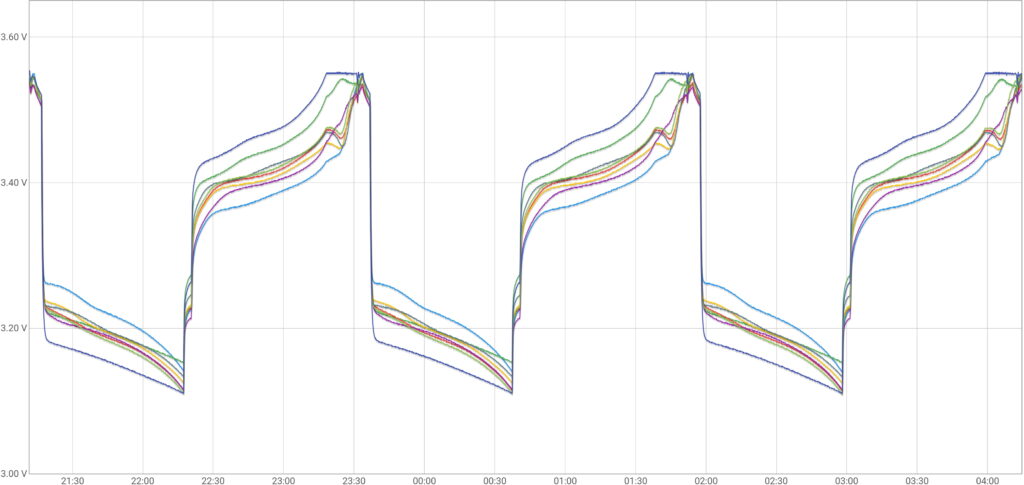

It goes without saying that completely randomly combined cells do not represent a useful second-life application. However, it has been demonstrated that such cells can be connected and operated in series and leveled using the straightforward ETA-Leveling process. This has been labelled disruptive – justifiably so – and can be completed in as little as a few hours. The resulting “patchwork battery” can be operated long-term without any issues. During charging, each cell is treated as if it was part of a single-cell battery application – thanks to efficiency leveling. This disproves the long-held assumption that the cells within a battery block need to be as identical as possible, and that even minor differences complicate or impede operation.

No more recycling unless a battery is actually defective

In light of large numbers of discarded battery modules piling up in manufacturer’s storage facilities and many more returning items that will join them in the years to come, this can be considered a revolutionary technology. Depending on a module’s designated application, it can retain as much as 80 % of its original capacity. Its current capacity results from individual, prematurely aged cells that unbalance the block and by doing so cause the actual defect. This means that the weakest cell within a module determines the entire block’s capacity. In turn, this translates to most of the cells within discarded battery blocks still being in excellent condition – or at least too good to recycle them. ETA-Leveling makes it possible to connect and operate very different cells in series: the first-of-its-kind, easy solution to continue to use these cells. “Up until recently, we ourselves would’ve never thought that combining cells randomly would work. It has not been possible with any of the traditional BMS,” says Frederik Fuchs, Managing Director of Benning CMS Technology. “Manufacturer, age, nominal capacity, cell chemistry – it really doesn’t matter. Our leveling process also recognises which cells are a reasonably sensible match based on their capacities. We then combine these cells to a long-lasting battery block that works perfectly.” This unlocks unprecedented opportunities for reusing discarded battery modules. Whether the aim is repurposing or processing to varying degrees (refurbishment, reconditioning, remanufacturing) – all possible scenarios become significantly more simple.

Licences for ETA-Leveling, which is suitable for battery blocks of all kinds and requires no hardware changes, recently became available for purchase.

Images:

(Please note, this is screen resolution only. You can request print resolution quality here.)

Please do not hesitate to contact us if you have any questions. If you had the opportunity to cover this information, we would much appreciate you sending us a link and/or a hard copy. If you are interested in an exclusive specialist article on the topic or a specific aspect of it, please reach out

to us.