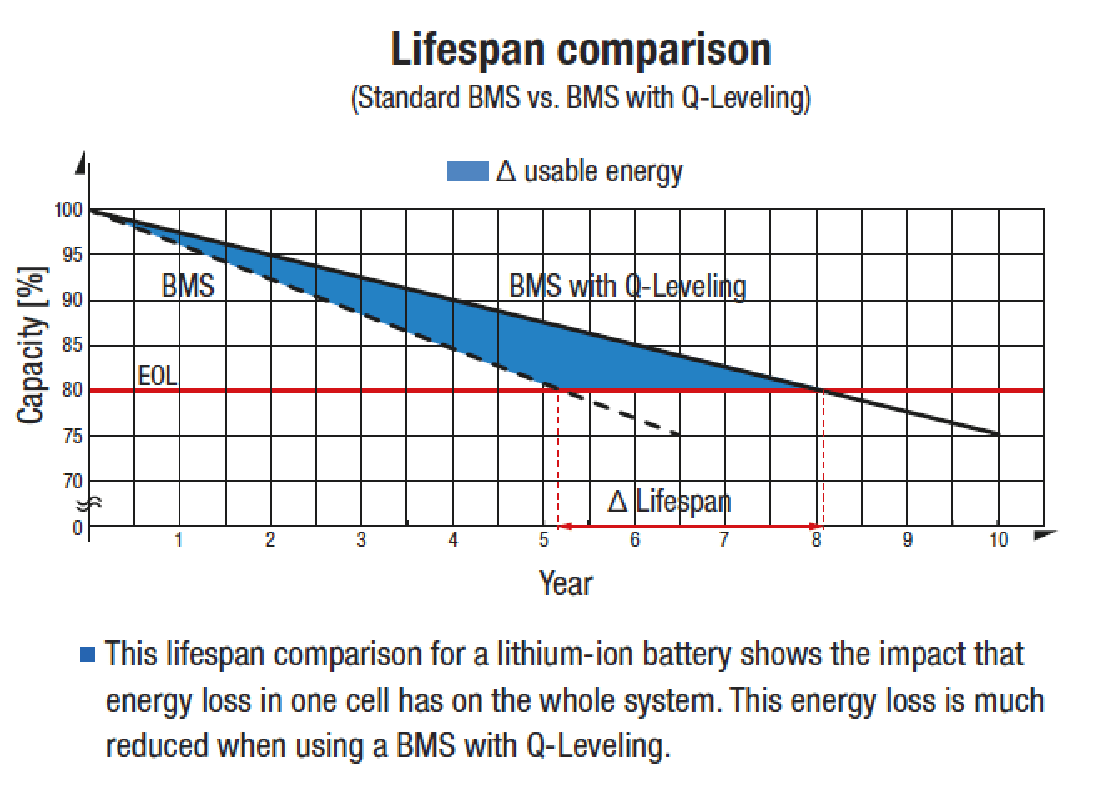

Days longer lifespan

NEXT LEVEL:

Lithium battery systems with a much increased lifespan

- Greater energy turnover

- Slower ageing process

- Improved data system

- Reduced maintenance

- Shorter charging times

- Better charging efficiency

BMS with Q-Leveling

Mit zunehmender Zyklisierung eines Batteriesystems unterliegt jede Zelle einem individuellen alterungsbedingten Kapazitätsverlust. Die so entstehenden Unterschiede zwischen den Zellen nehmen gewöhnlich mit der Zeit stark zu.

Bei einem BMS mit Q-Leveling erfolgt die Beurteilung des Systems nicht ausschließlich über Erkenntnisse aus den Spannungsverläufen der Zellen während des Ladens. Es nutzt zusätzlich eine individuelle dynamische „Kapazitätsmatrix“ mit Informationen über geringste Kapazitätsunterschiede zwischen den Zellen.

Anhand ausgefeilter Mess- und Steuerungsalgorithmen ist das Q-Leveling so in die Lage, die individuellen Ladezustände und alterungsbedingten Kapazitätsveränderungen aller einzelnen Zellen zu erkennen.

Über einen von den Lade- / Entladeströmen unabhängig regelbaren, sekundären Stromkreis kann jede einzelne Zelle fortwährend mit einem zusätzlichen, individuellen Strom beaufschlagt werden.

Die bisher bestehende Abhängigkeit, dass innerhalb einer Reihenschaltung allen Zellen immer der identische Strom aufgezwungen wird, ist durch das Q-Leveling aufgehoben – damit wird die Problematik, dass die schwächste Zelle in einer Reihenschaltung die Performance des Gesamtsystems bestimmt, gelöst.

Die im Verlauf eines Batterielebens innerhalb einer Reihenschaltung entstehende alterungsbedingte unterschiedliche Entwicklung der Zellkapazitäten durch das Q-Leveling wird verlangsamt und die negativen Auswirkungen können kompensiert werden.

In a BMS with Q-Leveling, the battery assessment process is not based exclusively on information from the voltage curves of the cells during charging. The system also uses a dynamic cell-specific “capacity matrix” containing information about minor differences in capacity between the cells.

- All cells can be assigned an individual charging or discharging current

- The weakest cells no longer determine the performance of the entire battery system

- Ageing is slowed, so there is less variation in the rate of capacity loss for the different cells

- Impacts of ageing are largely offset

As a battery system goes through more and more cycles, each cell experiences different rates of age-related capacity loss.

This results in differences between the cells, which usually become very pronounced over time.

Q-Leveling uses sophisticated measurement and control algorithms to identify the specific state of charge and age-related capacity loss of each individual cell.

Q-Leveling eliminates the traditional reliance on all cells connected in series always being supplied with identical currents – thus solving the problem of the weakest cell connected in series determining the performance of the entire system.

Over the lifetime of a battery, Q-Leveling reduces variation in the rate of age-related capacity loss for the different cells connected in series and offsets the negative impacts of this.

Benefits of a BMS with Q-Leveling

- Longer battery lifespan

- Possible to have significant variation between cells within a system

- Greater system energy turnover thanks to improved lifespan

- Cells are well preserved, slowing the ageing process of the individual cells

- Information about individual cells available at any time

- Defective cells can be easily replaced when needed

- Cost reduction through reliable lifespan planning (ROI)

- Cost reduction thanks to less necessary servicing and easier maintenance

- Shorter charging times

- More uniform ageing times of a system’s individual cells

- Ageing mechanisms are inhibited owing to higher cell voltages

Q-Leveling is ideal for:

-

Battery systems

• with large capacties

• with significant differences capacity between cells

• that comprise cells from different manufacturers - For retrofitting existing batteries with common BMS systems

Ideal geeignet für:

-

Batteriesysteme

• mit großen Kapazitäten

• mit großen Kapazitätsunterschieden zwischen den Zellen

• die aus Einzelzellen unterschiedlicher Hersteller aufgebaut werden - Zum Nachrüsten bestehender Batterien mit gewöhnlichen BMS-Systemen

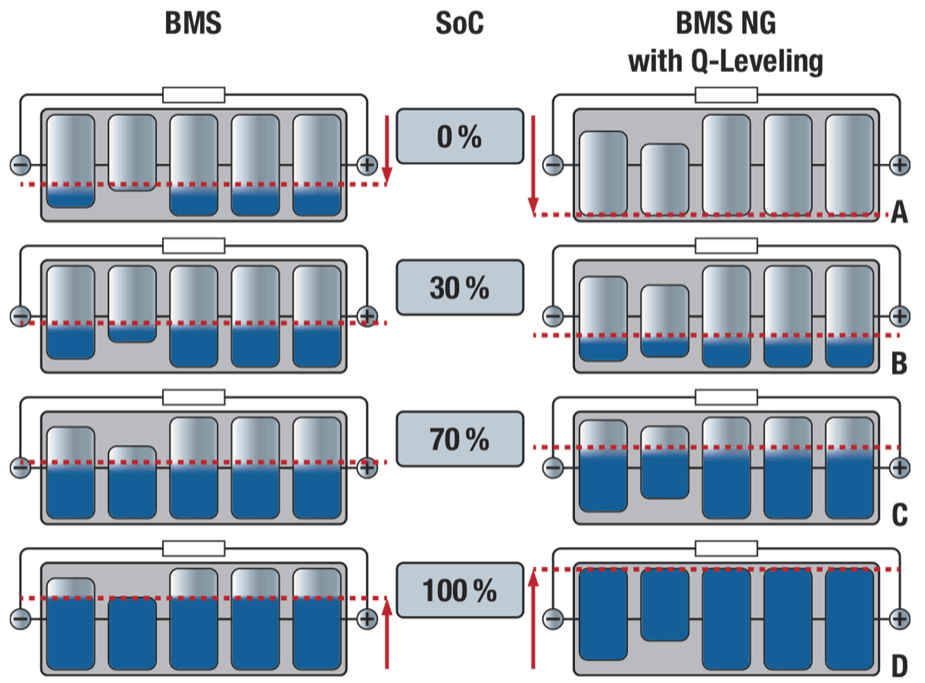

Advantages when operating the battery system

- The SoC of all cells remains almost identical, measured against the respective available cell useful capacity. The state of charge of the cells corresponds at all times to the state of charge of the entire battery (cell SoC = block SoC) (cf. B and C).

- The discharge process ends only when all cells are completely discharged. Usable energy can therefore be drawn from the battery for longer (cf. A).

- The weakest cell no longer reduces the useful capacity of all cells within the battery. The charging process only ends when all cells are fully charged. More usable energy is therefore available (cf. D).

- All cells reach their full state of charge almost simultaneously.

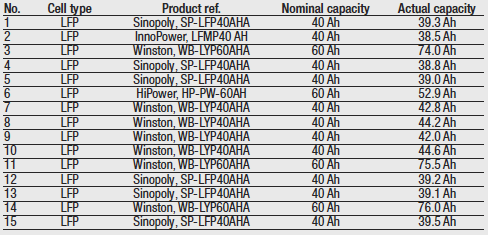

Scientific study

A scientific evaluation of the Q-Leveling process was carried out by Offenburg University of Applied Sciences. The aim of the study was to analyze the process and how it works

Methodology and verification of results

The study monitored a battery system for four days under test conditions. During this time, the system was put through several dynamic and abuse scenarios, and voltage, current and power measurements were taken at various measuring points. Fifteen cells, each with different capacities, were connected in series and managed using Q-Leveling. The maximum difference in capacity between the individual cells in the battery block was 96% (see table).

All the cells in the battery system were subsequently analysed under laboratory conditions, primarily to verify the capacity measurements generated by Q-Leveling for each individual cell.

SoC curve for the whole battery system

Despite the significant differences in capacity within the battery system, the state of charge (SoC) curves for the individual cells are almost identical.

The SoC for each individual cell aligns with the SoC for the whole system at all times.

Detailed view

For all cells to maintain the same SoC, each cell must be supplied with its own individual charging current during charging and discharging. This ensures that, despite their different capacities, the individual cells maintain almost the same SoC (based on their individual capacities).

Detaillierter Verlauf des Entladezustands

Am Beispiel dreier exemplarischer Zellen aus dem überwachten Batteriesystem.

• Bei gleichbleibendem Entladestrom in der Reihenschaltung entladen die Zellen mit unterschiedlichen individuellen Ladeströmen

• Trotz unterschiedlicher Zellkapazität entwickelt sich der SoC der einzelnen Zellen nahezu identisch

-

"The study found that the innovative circuit concept, which combines a series current with parallel currents for individual cells, performed well under test conditions.

The capacity management system (CMS) therefore proved itself effective.“(Quote from Offenburg University of Applied Sciences)

Note: CMS is the original name for the process now called Q-Leveling.

Summary of the facts

Q-Leveling works well with Lithium-ion batteries connected in series from different manufacturers, including where their capacities differ by almost 100% and for use cases with dynamic load profiles.

In addition to the current from the primary circuit, each cell is supplied with its own dynamic charging and discharging current from a secondary circuit. This ensures that, despite their significantly different capacities, all cells maintain approximately the same state of charge (SoC) at all times.

Q-Leveling can generate relevant information whenever required about the current charge level, overall capacity, current SoC, temperature, voltage and charging/discharging current. Almost identical state of charge (SoC) across all cells.

Opportunities for collaboration

There are many ways in which you can use the processes we have developed. For instance:

Licenced use

Licenced use

Retrofit / Second Life

Retrofit / Second Life

Development contract

Development contract

From initial designs to the development of the electronic components to the certification of the final product, we attend to all of the necessary tasks for you, including functional safety tasks.

Upon request, we will even take care of series production of the electronics afterwards. In this case, a use licence for the process can be precalculated into the price.

Make your ideas a reality

Make your ideas a reality

Licenced use

If you would like to rely on your own development resources, we would be happy to support and advise you during your development phase. We offer support for specific elements of individual phases of implementing the processes or for the entire development period in the form of regular workshops. The process-oriented algorithms can then be used on the basis of a licencing contract.

Development contract

Would you like to commission us to develop a battery management system for you? We would be happy to make you an offer for the development of a customised BMS including Q-Leveling.

From initial designs to the development of the electronic components to the certification of the final product, we attend to all of the necessary tasks for you, including functional safety tasks.

Upon request, we will even take care of series production of the electronics afterwards. In this case, a use licence for the process can be precalculated into the price.

Retrofit / Second Life

Battery systems that are no longer usable due to excessive misalignment in the cell network can be reactivated with a subsequently installed Q-leveling process.

Make your ideas a reality

Do you have ideas about how you can benefit from the potential our processes offer? Let us know – whether you are looking to develop a completely new product or if you would like to secure the exclusive rights for use in a specific industry.

Many ways - one goal

BENNING CMS Technology GmbH

Founded in 2017, BENNING CMS Technology GmbH is a company which specialises in the new development of battery management systems (BMS) and their technical implementation for lithium battery systems.

We have since patented two revolutionary processes for lithium battery system operation which are more efficient and economical, and which better preserve the battery system. We have also applied for patents for even more ideas.

Am Untergrün 6 • 79232 March

Phone: 0049 (0)7665 52372-72

Fax: 0049 (0)7665 52372-99

info@cms-technology.de

www.cms-technology.de