optimized lithium battery systems

Long lifespan for

lithium battery systems

- higher energy expenditure

- slower ageing

- better data situation

- less necessary servicing

- shorter charging times

- higher charging efficiency

BMS with ETA-Leveling

η-Leveling is a process driven by cell conversion efficiency. Through targeted correction of the conversion efficiency, all cells connected in series are levelled so that all cells in the system have a uniform overall efficiency and thus achieve the end-of-charge voltage at the same time.

Benefits of a BMS with η-Leveling

- Longer battery lifespan

- Greater system energy turnover thanks to improved lifespan

- Cells are well preserved, slowing the ageing process of the individual cells

- Cost reduction through reliable lifespan planning (ROI)

- Cost reduction thanks to less necessary servicing and easier maintenance

- Shorter charging times

- More uniform ageing times of a system’s individual cells

- Ageing mechanisms are inhibited owing to higher cell voltages

Simulation

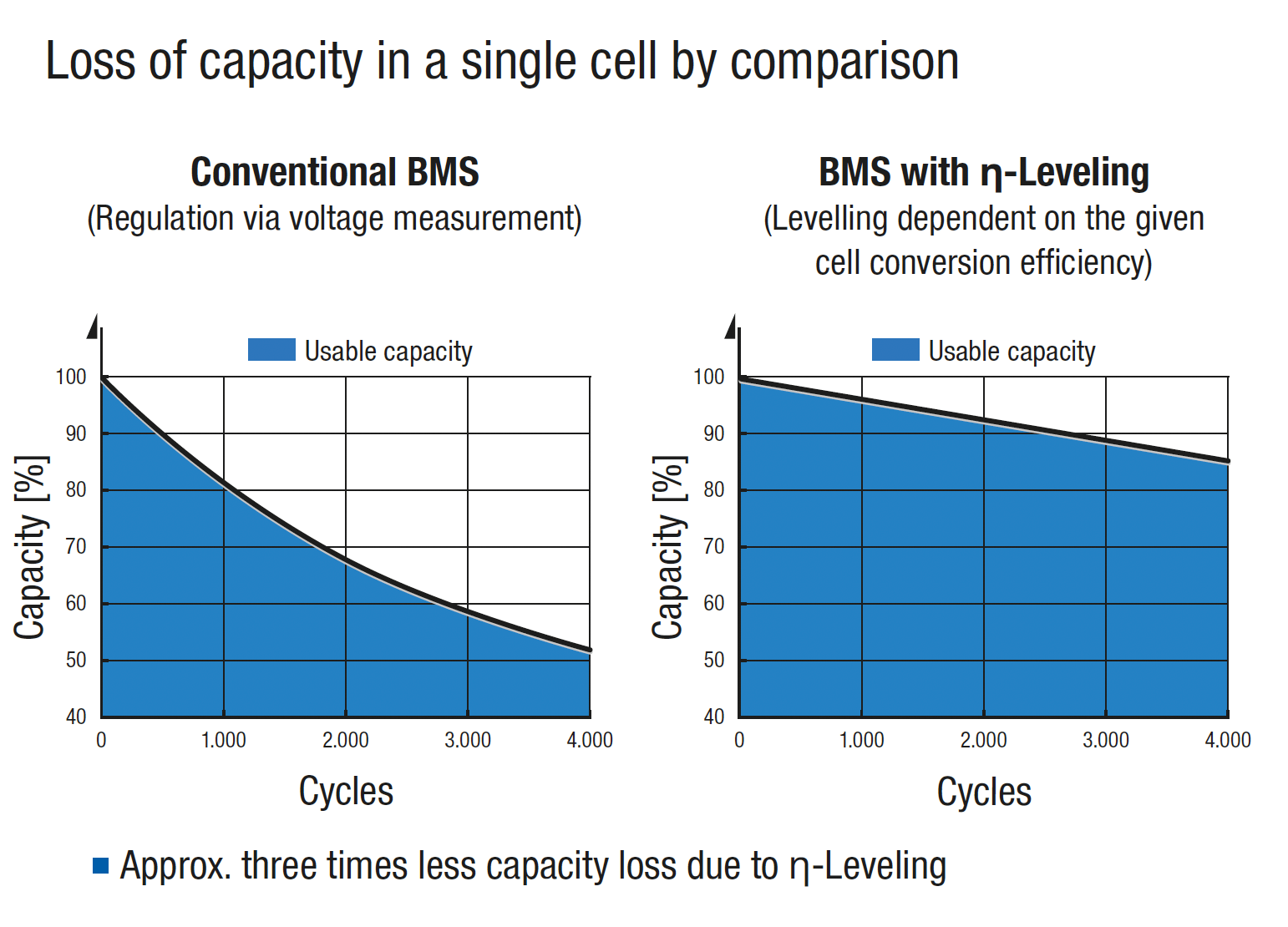

The results of a simulation demonstrating the differences between a battery block with a conventional BMS and our BMS with η-Leveling are shown below.

The effects that the battery management system has on individual cells’ ageing processes are clearly illustrated.

Cells are known to age more quickly due to:

• Being left untouched at high cell voltages

• High depths of discharge and thus a deep discharge

• High temperatures

The BMS used should take this general knowledge into consideration.

Simulation design

This simulation compared two battery systems. While one was equipped with a conventional BMS typically seen on the market, the other had a BMS with η-Leveling.

System constructions

• Three LFP cells connected in series (pack)

• Capacity: 200 Ah

• Internal impedance: 0.8 mΩ

• Variation of self-discharge: 8, 10, 12 mA

• Charging/discharging: CC of 50 A

Test procedure

1. Discharge down to 80% DoD, or until the first cell has reached the end-of-discharge voltage

2. ten-minute break

3. Charge until the first cell has reached the end-of-charge voltage

4. Balancing (if necessary)

5. Ten-minute break

(Repeat for 10.000 cycles or until 40 % SoH is reached.)

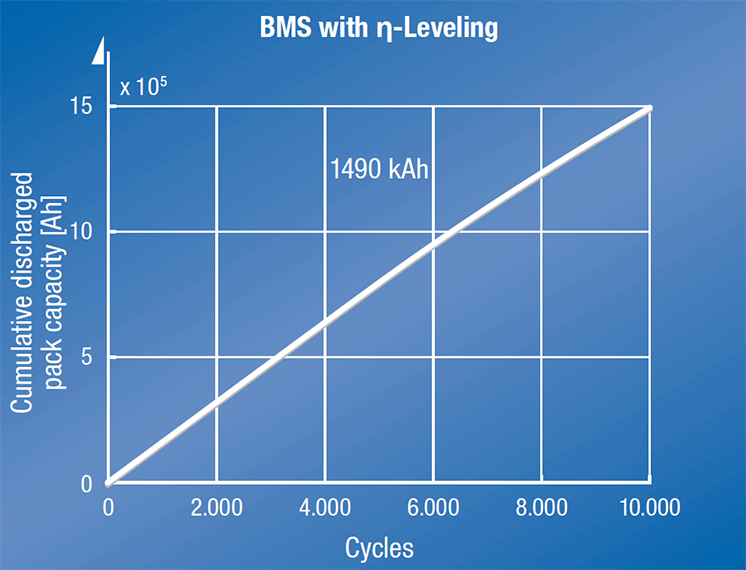

Cumulative discharged pack capacity

Benefits:

• Longer lifespan

• More than double the charging cycles possible

• Approx. three times more useable energy

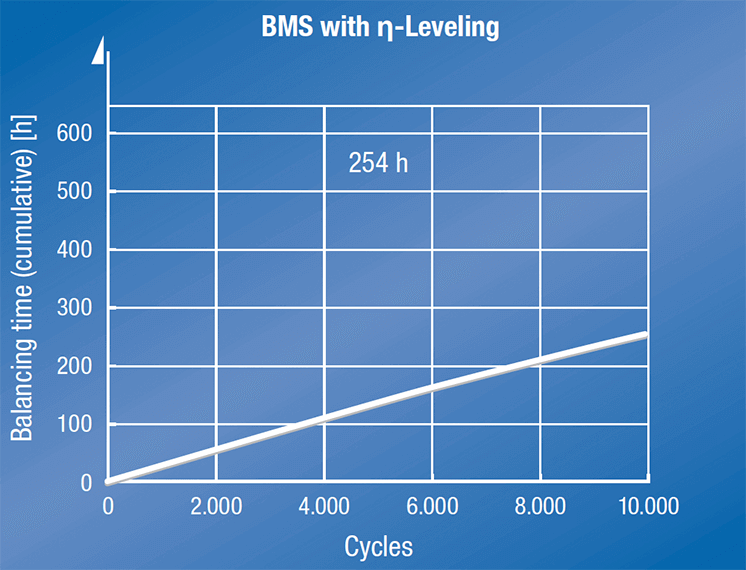

Cumulative power-on time of the balancing resistors

Benefits:

• Significantly quicker charging times since the BMS with η-Leveling levels the cells throughout the entire charging cycle

Cumulative discharged pack capacity

Benefits:

• Longer lifespan

• More than double the charging cycles possible

• Approx. three times more useable energy

Cumulative power-on time of the balancing resistors

Benefits:

• Significantly quicker charging times since the BMS with η-Leveling levels the cells throughout the entire charging cycle

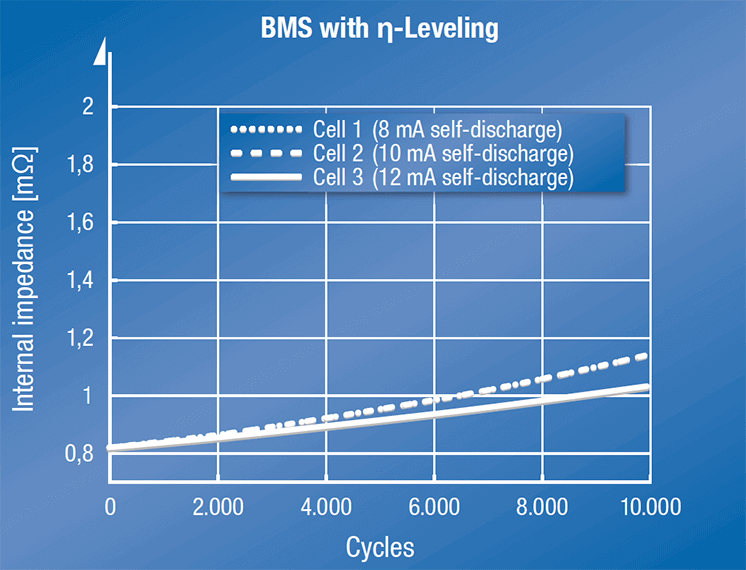

Increase in internal impedance

Benefits:

• Substantially slower cell ageing process, smaller increase in internal cell impedance

• Less variation in internal cell impedance values within a pack

• After more than 10,000 cycles, the test packet’s end of life was still not reached

Summary of the facts

In comparison to a conventional Battery-Management-Systems, equipping a battery with a BMS with η-Leveling:

• Provides for significantly slower ageing

• Achieves more than twice the useable capacity

• Enables up to five times greater balancing efficiency

Additionally, BMSs with η-Leveling are:

• No more expensive to manufacture than conventional BMSs

• Compatible with existing hardware designs

A η-Leveling upgrade is currently available for all existing BMSs from known manufacturers.

Opportunities for collaboration

There are many ways in which you can use the processes we have developed. For instance:

Licenced use

Licenced use

Upgrade of your existing system

Upgrade of your existing system

Development contract

Development contract

From initial designs to the development of the electronic components to the certification of the final product, we attend to all of the necessary tasks for you, including functional safety tasks.

Upon request, we will even take care of series production of the electronics afterwards. In this case, a use licence for the process can be precalculated into the price.

Make your ideas a reality

Make your ideas a reality

Licenced use

If you would like to rely on your own development resources, we would be happy to support and advise you during your development phase. We offer support for specific elements of individual phases of implementing the processes or for the entire development period in the form of regular workshops. The process-oriented algorithms can then be used on the basis of a licencing contract.

Development contract

Would you like to commission us to develop a battery management system for you? We would be happy to make you an offer for the development of a customised BMS including η-Leveling. From initial designs to the development of the electronic components to the certification of the final product, we attend to all of the necessary tasks for you, including functional safety tasks. Upon request, we will even take care of series production of the electronics afterwards. In this case, a use licence for the process can be precalculated into the price.

Upgrade of your existing system

Make your ideas a reality

Many ways - one goal

BENNING CMS Technology GmbH

Founded in 2017, BENNING CMS Technology GmbH is a company which specialises in the new development of battery management systems (BMS) and their technical implementation for lithium battery systems.

We have since patented two revolutionary processes for lithium battery system operation which are more efficient and economical, and which better preserve the battery system. We have also applied for patents for even more ideas.

Am Untergrün 6 • 79232 March

Phone: 0049 (0)7665 52372-72

Fax: 0049 (0)7665 52372-99

info@cms-technology.de

www.cms-technology.de

Last modified: 07/2023 | Imprint | Privacy Policy | Copyright @ BENNING CMS Technology GmbH